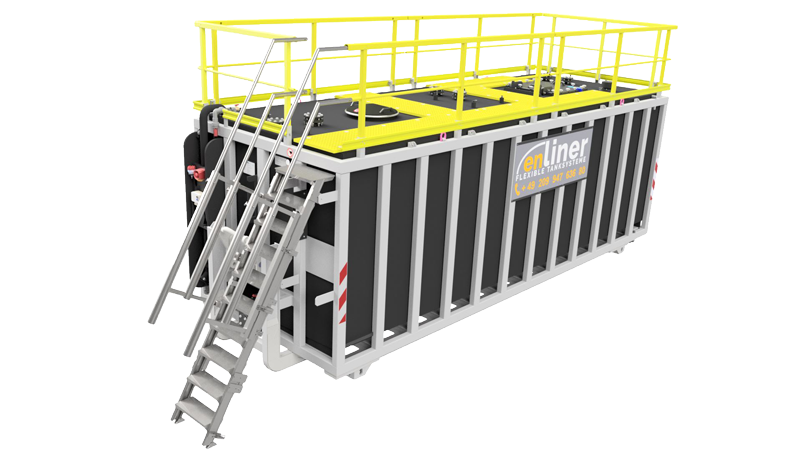

30m3 DOUBLE WALL POLYTANK

With a capacity of up to 30,000 litres, the Double Wall Polytank offers excellent opportunities for the temporary storage of aggressive liquids. The double-wall construction allows for safe, easy and continuous monitoring to protect against leaks. Flexible and reliable to use, designed for safety, easy maintenance and cleaning.

FEATURES & BENEFITS

- Double-wall construction for optimal environmental protection

- Resistant to acids, alkalis and aggressive liquids

- All flanges and connections according to DIN standard

- Static drain

- Easy cleaning without entering

- Short installation time

APPLICATIONS

We support customers from refineries, industrial plants, waste water treatment plants, chemical plants, power plants and drilling companies.

Applications include:

- Shutdowns and Turnarounds

- Maintenance projects

- Cleaning projects

- Emergencies (damages, leaks, etc.)

| Dimensions & Construction | |

| Capacity | 30,000 Litres (30m3) |

| Dimensions | (h) 2,088 x (w) 2,249 x (l) 6,719 mm (inside) (h) 2,700 x (w) 2,550 x (l) 7,450 mm (transport) (h) 3,600 x (w) 2,550 x (l) 8,700 mm (service) |

| Transport | · Standard hook lift system for roll-off containers (adjustable for different country systems) · 4 x crane eyes for lifting when empty |

| Material | · Polyethylen (Tank body) · Transport-/steel frame made of S235 JR (coated) |

| Max. density | 1,80 t/m3 |

| Operating pressure | Unpressurised |

| Temperature | 40 °C (> 40 °C on request) |

| Column 1 Value 8 | Column 2 Value 8 |

| Features & Accessories | |

| Connection (front) |

· Flanged ball valve DN 50 (housed) on the floor · Filling pipe with DN 80 flange (electrically conductive) |

| Connection (roof) |

· 3 x DN100 DIN-Flange, 1x dip pipe Ø 90 mm · 3 x DN80 DIN-Flange, 1x dip pie Ø 70 mm · 1 x sampling port with screw cap Ø 80 mm |

| Ladder | Foldable aluminum ladder with handrails and railings around the entire work platform. Gratings for safe access to the tank. |

| Level gauge | Mechanical level gauge |

| Monitoring |

· 1 x signal control (electric) |

| Application | Acids, alkalis and aggressive liquids as well as other liquids on request |

| Construction testing |

Manufactured in Germany · Suitability test according to AwSV/WHG by TÜV Nord based on DVS 2205 · EU Declaration of Conformity · Structural approval · Steel frame according to DGUV 114010 |

| Pressure testing | Regular pressure test before each use with 100 mbar for 30 minutes |

| Inspection | · Regular leak test · Every 5 years internal and external inspection of the welding seams and material assessment by an authorised expert for plastics technology · Extensive inspections when required or after repairs |