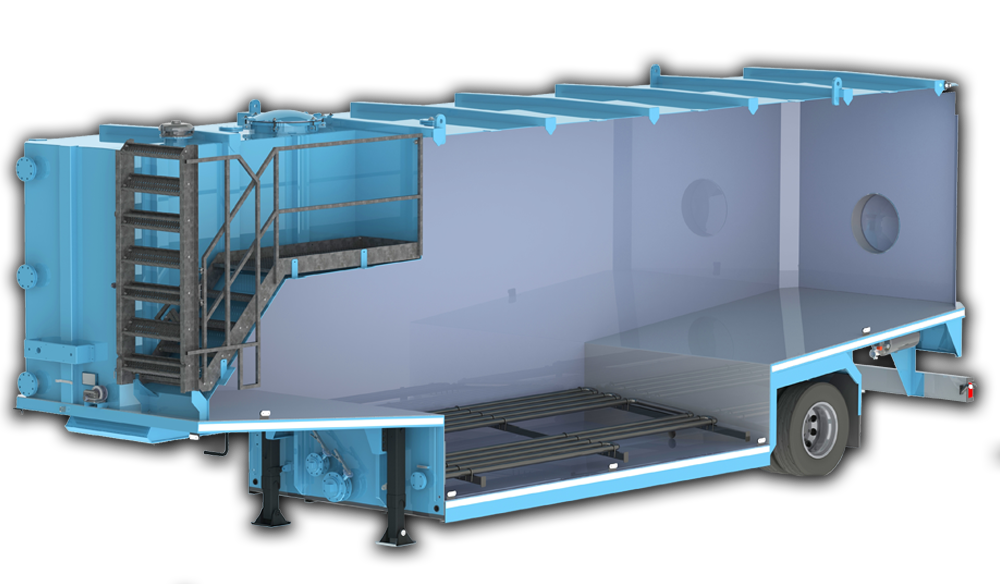

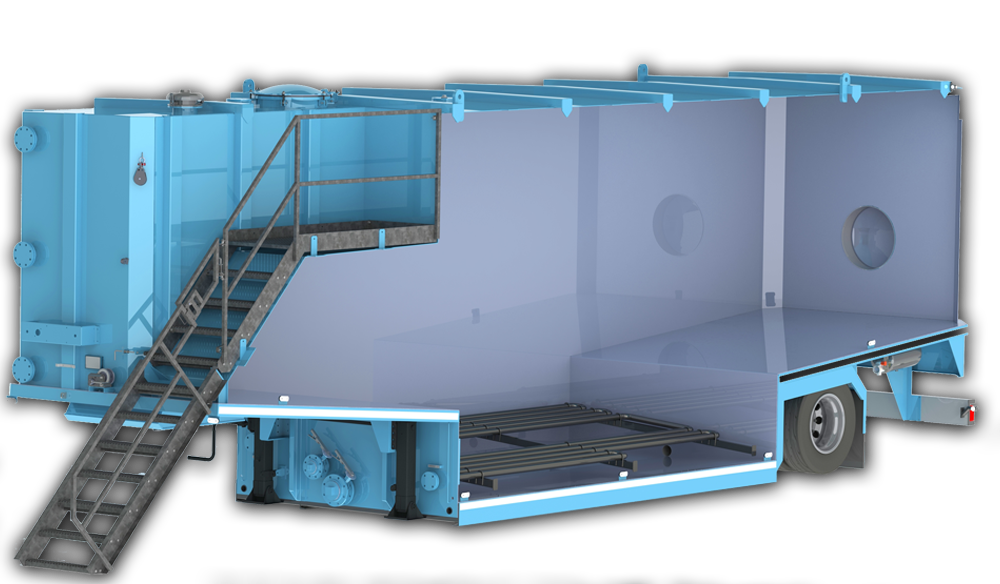

70m3 COIL TANK

The mobile Coil Tank provides both storage and heating for temporary liquid handling and processing.

The tank is fitted with steam coils in a continuous sloped serpentine loop and provides high efficiency heat transfer from steam to the stored liquid while avoiding condensate build-up during the process.

The mobile Coil Tank variant has been designed, tested and CE certified for safety, process functionality and transport throughout Europe.

SPECIFICATIONS

FEATURES & BENEFITS

- Protection against zero degree temperatures by maintaining liquid above the liquid freezing point

- Liquid temperature control for thermal sensitive process applications

- Liquid viscosity control for dense liquid movement applications

- Continuous serpentine configuration for high efficiency heat transfer

- Sloped and inclined configuration for the elimination of condensate build-up

- High pressure input and output connections for customer supplied steam services

- Field tested for safety adherence and process functionality

- V-sloped main floor for trouble-free cleaning

- Refined pneumatically-actuated rear suspension system ensures safe operation when raising and lowering

- Mechanical locking system for safe on road transport

- Remote valve actuation at the rear of the tank for tank filling and draining

- Integrated staircase ensures personnel protection, giving access to all upper manways, gauges, and connection points

- Large capacity on small footprint

- Transported and installed without the need for any plant lifting equipment

| Dimensions & Construction | |

| Capacity | 70,000 Litres (70m3) |

| Length | 11,667 mm |

| Width | 2,530 mm |

| Height | 3,970 mm (Transport) 3,780 mm (Service) |

| Weight | approx. 12,870 kg (empty) |

| Temperature | 70°C max. continuous (uncoated) |

| Specific Gravity | Max. specific gravity of 1.6 non-hazardous chemicals |

| Available Elastomers | Viton®/FKM Buna-N/NBR EPDM |

| Features & Accessories | |

| Ladder | Integral fold-down ladder for safe access to landing |

| Access | 3 x 600mm hinged manways (roof, rear, side) |

| Pipe & Hose Connections | 6 x DN 100 N16 Flanges (2 x roof, 4 x front – separator style) |

| Drain Valves | DN150 PN16 (front) DN100 PN16 (rear) |

| Safety Valve | 1 x Thief hatch, Buna-N®/NBR gasket, pressure setting 69m Bar, vacuum setting 1.3mmHg |

| Level Gauge | Roof-mounted dial gauge (optional) |

| Hydrostatic Testing | Hydrostatic water test during construction; retested during repairs and regular maintenance |

| Steam Coils | |

| Pressure Tested | Steam coils have been pressure tested to 20.7 bar under the pressure equipment directive |

| Recommended customer steam input services |

Inlet steam pressure: 10-10.5 bar Inlet steam mass flow: 190-220 kg/h Inlet steam temperature: 180-195°C Based on 55,000 litres of clean water the following temperature parameters have been achieved: Average steam coil temperature: 34.75°C Average liquid temperature increase per hour: 1.89°C/h Please contact Rain for Rent for further details. Due to meticulous testing completed on the steam coil tanks, Rain for Rent can provide solid application support for desired liquid temperature parameters on a wide range of liquid types |

| Heating Coil Connections | DN50 (2″) steel piping with DN50 PN40 inlet/outlet flanged connections

|