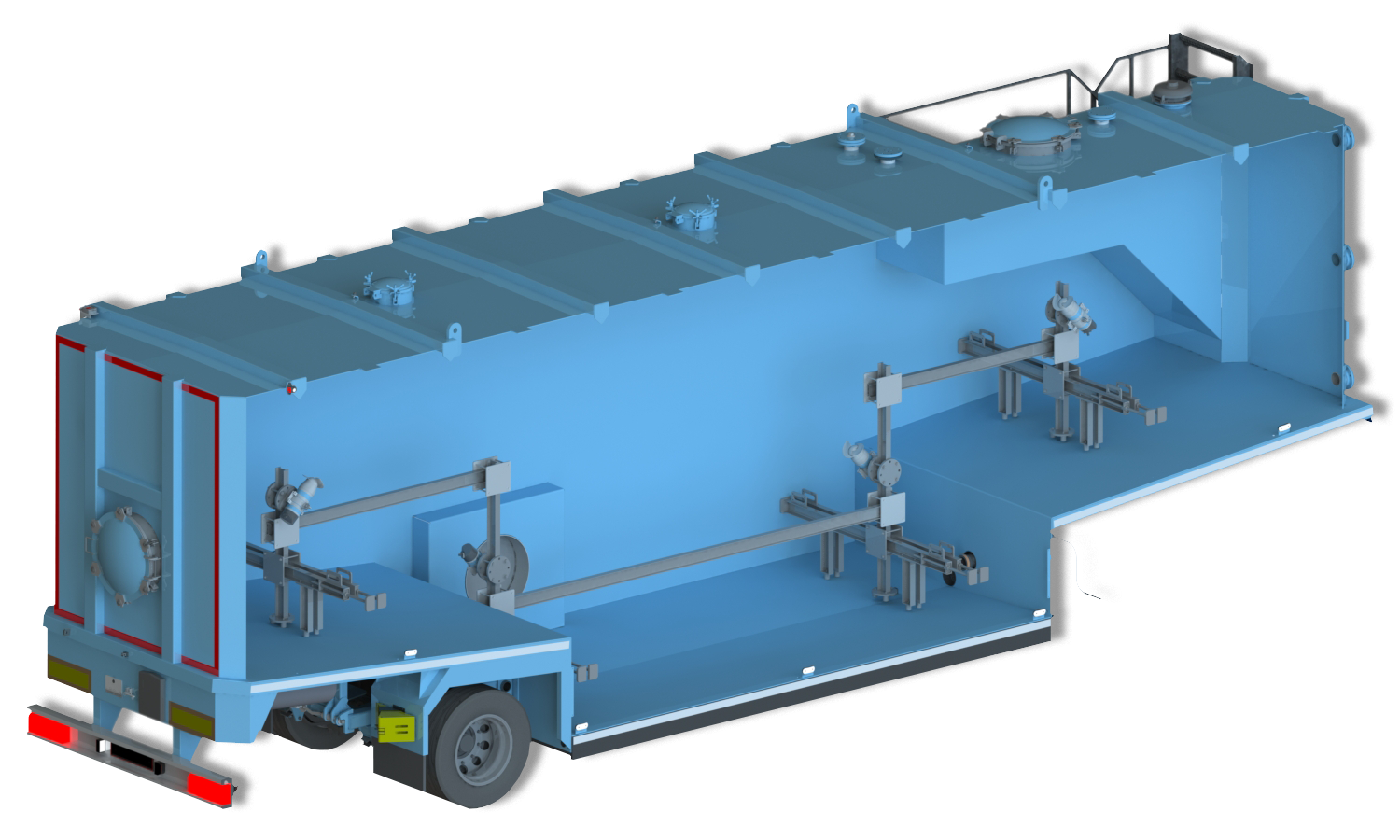

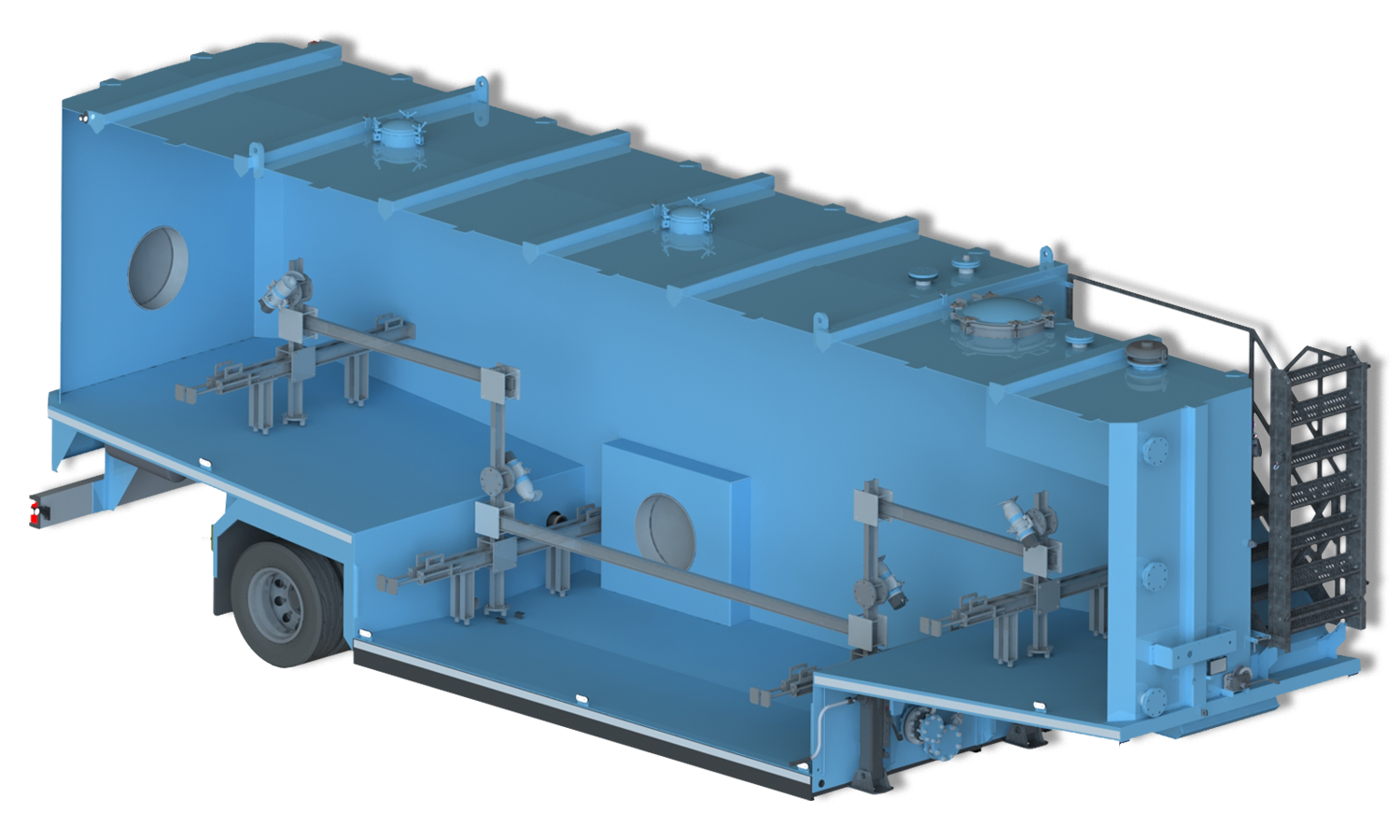

70m3 MIXER TANK

The Standard or Coil Tanks can swiftly be turned into Mixer Tanks by installing two to four compact agitators.

Utilising compact mixers, which easily blend high-density or high-viscosity liquids, is the choice for a broad range of mixing applications.

The tank can easily and safely be transported throughout Europe.

FEATURES & BENEFITS

- Steady and specially designed steel constructions hold the compact mixers in place

- Alignment of mixers for efficient turbulence and bulk-flow allowing the contents of the entire tank to be set in motion involved in the mixing process

- Permanently attached axels for maximum manoeuvrability allow this 70m3 Tank to be moved with ease on the project site

- Refined pneumatically-actuated rear suspension system ensures safe operation when raising and lowering the tank

- Mechanical locking system for safe on road transport

- Transported and installed without the need for a crane

- V-sloped main floor for trouble-free cleaning

SPECIFICATIONS

| Dimensions & Construction | |

| Capacity | 70,000 Litres (70m3) |

| Length | 11,667 mm |

| Width | 2,530 mm |

| Height | 3,970 mm (Transport) 3,780 mm (Service) |

| Specific Gravity | Max. specific gravity of 1.6 of non-hazardous chemicals |

| Available Elastomers | Viton®/FKM, Buna-N/NBR, EPDM |

| Features & Accessories | |

| Ladder | Integral fold-down ladder for safe access to landing |

| Access | 3 x 600mm hinged manways (roof, rear, side) |

| Cleaning Access | 2 x 300 mm access hatch for cleaning nozzles (featured on all Standard Tanks post 2019) |

| Pipe & Hose Connections | 6 x DN 100 N16 Flanges (2x roof, 4x front – separator style) |

| Drain Valves | DN150 PN16 (front) DN100 PN16 (rear) |

| Level Gauge | Roof-mounted dial gauge (optional) |

| Compact Mixer SR4620 |

|

| Application Limits | |

| Liquid Temperature | Maximum 40°C |

| Liquid Viscosity/ Medium Density |

Maximum 5000 cp / 1100 kg/m3 |

| pH | 1-12 |

| Motor Data | |

| Type | Induction motor with 4-pole squirrel cage |

| Frequency | 50 Hz |

| Power Supply | Single phase or three phase |

| Maximum Number of Starts Per Hour | 30 starts per hour at regular intervals |

| Standard Elastomers | Buna-N/NBR |

| Approvals | |

| European Standard (EN) |

|

| EN Approval for Cable Entry |

|

| IEC |

|

| FM Approvals |

|